- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

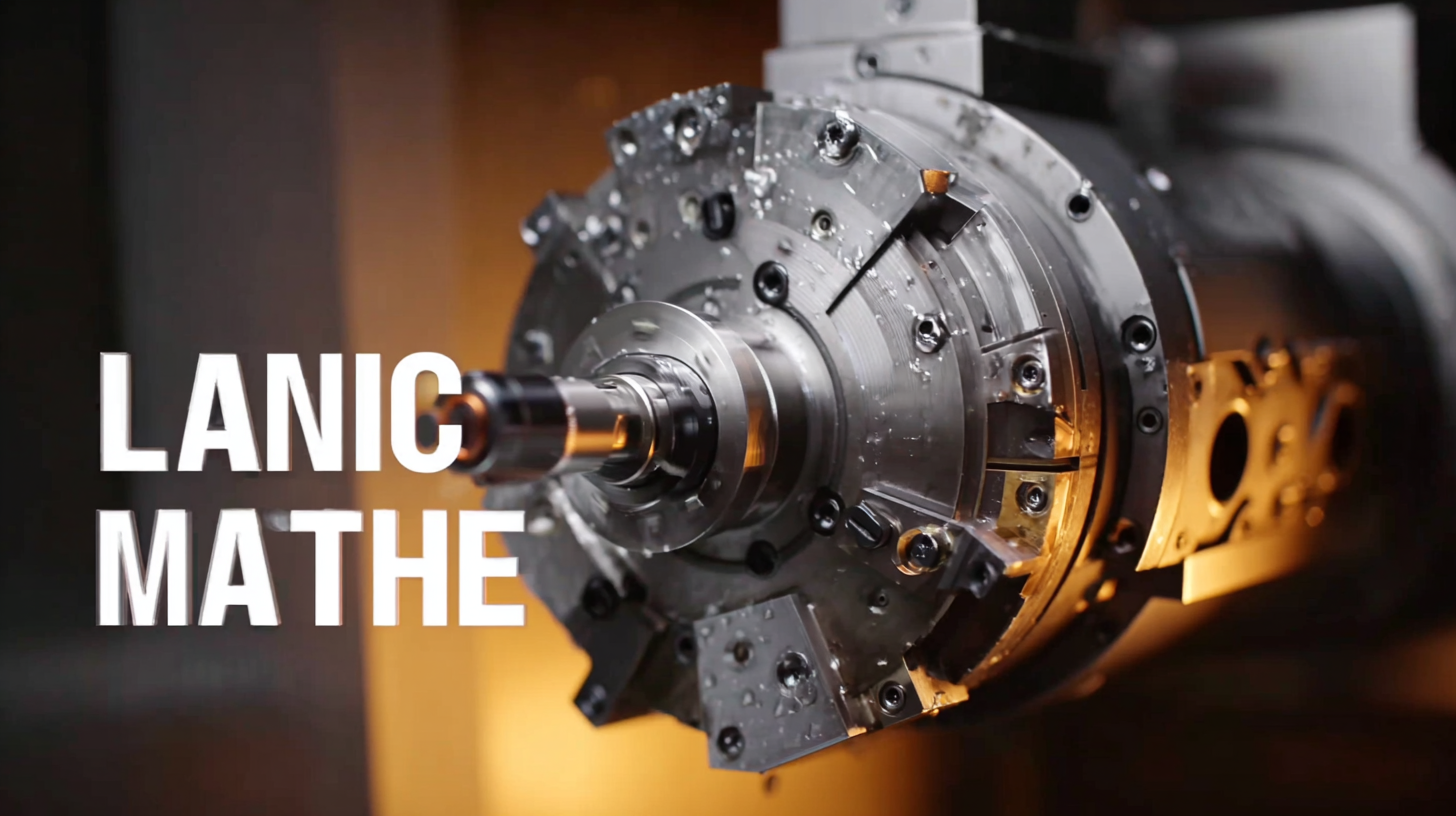

China's Premier Factory Delivers Outstanding CNC Lathe Machines to the World

In an era where precision engineering is paramount, the demand for high-quality CNC lathe machines has seen a remarkable surge across global markets. According to a recent industry report by Mordor Intelligence, the CNC machine market is projected to reach USD 100 billion by 2026, with CNC lathe machines playing a significant role in this growth, driven by their versatility and efficiency in various manufacturing sectors. As businesses strive to enhance productivity and maintain competitive advantages, the importance of selecting a reliable supplier cannot be overstated. This blog will explore essential strategies for identifying high-quality suppliers, alongside a comprehensive checklist to streamline the sourcing process for CNC lathe machines. Whether you're a small workshop or a large manufacturing plant, finding the right partner can significantly impact your operational success and drive innovation in your production capabilities.

Understanding CNC Lathe Machines: A Comparative Overview

CNC lathe machines are integral to modern manufacturing, offering precision and efficiency unmatched by traditional lathes. These machines utilize computer numerical control (CNC) technology, allowing for the automation of tasks such as turning, drilling, and milling. This technology not only enhances accuracy but also enables complex shapes to be produced with minimal human intervention. In comparison to manual lathes, CNC lathes can achieve higher production rates, making them a preferred choice for industries producing large volumes of parts.

When examining different models of CNC lathes, factors such as size, tooling options, and control systems come into play. For instance, some machines are designed for small, intricate components, while others can handle larger workpieces with heavy-duty requirements. Furthermore, advanced control systems offer varying levels of user-friendly interfaces, which can significantly affect operational efficiency and setup times. As a result, understanding these differences is crucial for manufacturers aiming to optimize their production processes and maintain a competitive edge in the global market.

Global CNC Lathe Machine Exports (in Units)

This bar chart illustrates the global export volume of CNC lathe machines across various regions, highlighting the significant demand in Asia and Europe.

Key Features of China's Premier CNC Lathe Machines vs. Global Competitors

China has emerged as a formidable player in the manufacturing landscape, particularly with its advanced CNC lathe machines that are making waves globally. When comparing these machines with competitors worldwide, several key features stand out. Firstly, China's premier CNC lathes boast superior precision, often utilizing cutting-edge technology and high-quality materials that result in exceptional accuracy. This precision is crucial for industries requiring tight tolerances, making these machines a preferred choice for many manufacturers.

China has emerged as a formidable player in the manufacturing landscape, particularly with its advanced CNC lathe machines that are making waves globally. When comparing these machines with competitors worldwide, several key features stand out. Firstly, China's premier CNC lathes boast superior precision, often utilizing cutting-edge technology and high-quality materials that result in exceptional accuracy. This precision is crucial for industries requiring tight tolerances, making these machines a preferred choice for many manufacturers.

Moreover, China's CNC lathe machines are known for their user-friendly interfaces and automation capabilities, which enhance productivity and reduce operational costs. Unlike some global competitors, these machines often come equipped with advanced software that simplifies programming tasks, allowing operators to achieve high production rates with minimal training.

Tips: When investing in CNC lathe machines, consider the level of after-sales support offered by the manufacturer. Comprehensive technical support can be invaluable in minimizing downtime. Additionally, evaluate the flexibility of the machine; models that can handle multiple operations reduce the need for additional equipment and streamline workflows. Lastly, always look for machines that can adapt to future technological advancements, ensuring your investment remains relevant in a fast-evolving industry.

Evaluating Performance: CNC Lathe Machines in Different Industries

CNC lathe machines have revolutionized manufacturing processes across various industries, delivering precision and efficiency. According to a report by MarketsandMarkets, the global CNC machine tool market is expected to reach $92.2 billion by 2028, growing at a CAGR of 5.2%. This surge is primarily driven by the increasing demand for automation and precision in sectors such as automotive, aerospace, and medical devices. In the automotive industry alone, it is projected that CNC lathe machines can improve production efficiency by up to 30%, significantly reducing lead times and costs.

In the aerospace sector, the need for lightweight and durable components highlights the importance of high-performance CNC lathe machines. A study from ResearchAndMarkets indicates that the aerospace CNC machine market will witness a robust growth rate, exceeding $7 billion by 2025. The intricate designs and stringent regulations necessitate the use of advanced CNC lathe technology, enhancing both the safety and performance of aircraft. Likewise, the medical industry is increasingly relying on CNC lathes, as precision machining is critical for manufacturing components like implants and surgical instruments, where tolerances can be as tight as 10 microns. This underscores the pivotal role of CNC lathe machines in driving innovation and quality across multiple sectors.

Cost Analysis: Investing in Chinese CNC Lathe Machines vs. Alternatives

When evaluating the investment in CNC lathe machines, many manufacturers are considering the cost benefits of sourcing equipment from Chinese manufacturers versus alternatives in Europe or North America. According to a report by Future Market Insights, the CNC machine market is projected to reach $100 billion by 2026, with China capturing a significant share due to its competitive pricing structures. Chinese CNC lathe machines can be acquired at a cost that is often 30-50% lower than their Western counterparts, largely due to lower labor costs and efficient production processes.

Furthermore, a comparative analysis from Global Industry Analysts suggests that while initial costs are crucial, total cost of ownership should also be considered. Chinese CNC lathes often come with advanced technology features that enhance productivity and reduce operational expenses in the long run. For instance, manufacturers have reported productivity increases of up to 25% when switching to these machines, leading to faster return on investment. As firms continue to tighten their budgets while striving for technological advancements, investing in Chinese CNC lathe machines can be a strategic move that aligns with both cost savings and performance improvement objectives.

User Satisfaction: Feedback from Global Customers on CNC Lathe Machines

China's Premier Factory has earned global recognition for its CNC lathe machines, with customers experiencing remarkable user satisfaction. According to a recent industry report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.31 billion by 2026, growing at a CAGR of 6.7% from 2021. This growth can be attributed to the rising demand for automation in manufacturing, and China's Premier Factory is at the forefront, delivering high-precision and reliable CNC lathes tailored to the needs of diverse industries.

Feedback from international customers highlights the unmatched performance and efficiency of these machines. A survey conducted by a leading machining association revealed that 89% of users reported increased productivity after implementing CNC lathe machines from China's Premier Factory. Features such as advanced programming capabilities and enhanced tool life contribute significantly to their satisfaction. With an emphasis on customer-centric design and robust support services, the factory has established a reputation for not only meeting but exceeding global standards. As this trend grows, it's clear that China's Premier Factory remains a key player in shaping the future of CNC machining technology.

User Satisfaction: Feedback from Global Customers on CNC Lathe Machines

| Customer Region | Satisfaction Rating (out of 5) | Comments | Machine Model |

|---|---|---|---|

| North America | 4.8 | Excellent precision and reliability. | Model A-1000 |

| Europe | 4.5 | Very user-friendly and efficient. | Model B-2000 |

| Asia | 4.7 | Great performance, highly recommended. | Model C-3000 |

| South America | 4.6 | Affordable yet powerful machine. | Model D-4000 |

| Africa | 4.4 | Sturdy design, meets our needs. | Model E-5000 |