- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Understanding Import Export Certifications for Best CNC Lathe Machine Purchases

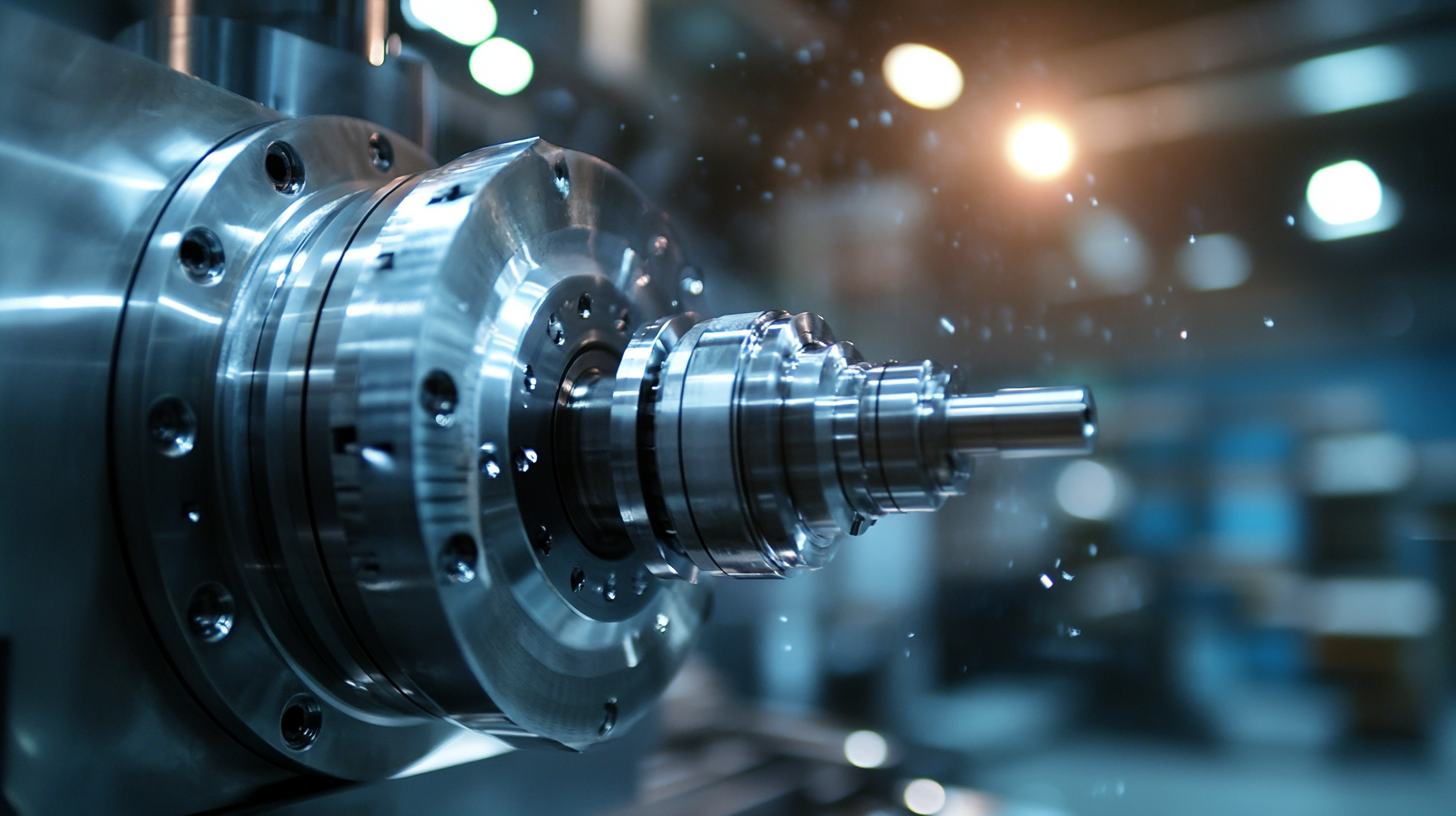

In the competitive landscape of manufacturing, the procurement of a high-quality CNC Lathe Machine is pivotal for ensuring precision and efficiency in production processes. According to a report by MarketsandMarkets, the global CNC lathe machine market is projected to reach USD 5.65 billion by 2025, growing at a CAGR of 7.1% from 2020. This growth underscores the increasing reliance on advanced machining technologies across various industries. As businesses strive to enhance their capabilities, understanding the necessary import-export certifications becomes critical when sourcing from suppliers. Selecting the right CNC Lathe Machine is not solely about the price; it involves a comprehensive evaluation of supplier credibility, product quality, and compliance with international standards. In this blog, we will explore the effective strategies for identifying reputable suppliers and navigating the complexities of certifications to ensure that your investment in CNC lathe machinery is both informed and advantageous.

In the competitive landscape of manufacturing, the procurement of a high-quality CNC Lathe Machine is pivotal for ensuring precision and efficiency in production processes. According to a report by MarketsandMarkets, the global CNC lathe machine market is projected to reach USD 5.65 billion by 2025, growing at a CAGR of 7.1% from 2020. This growth underscores the increasing reliance on advanced machining technologies across various industries. As businesses strive to enhance their capabilities, understanding the necessary import-export certifications becomes critical when sourcing from suppliers. Selecting the right CNC Lathe Machine is not solely about the price; it involves a comprehensive evaluation of supplier credibility, product quality, and compliance with international standards. In this blog, we will explore the effective strategies for identifying reputable suppliers and navigating the complexities of certifications to ensure that your investment in CNC lathe machinery is both informed and advantageous.

Importance of Import Export Certifications in CNC Machinery Purchasing

When purchasing CNC machinery, understanding import export certifications is crucial for ensuring compliance and optimal operational efficiency. According to a recent industry report by MarketsandMarkets, the global CNC machine tools market is projected to reach $120 billion by 2026, with certifications playing a significant role in driving this growth. Import export certifications not only assure product quality and safety but also streamline the procurement process, allowing businesses to avoid costly delays and penalties associated with non-compliance.

Tip: Always check that your CNC lathe machine supplier provides the necessary certifications such as CE, ISO 9001, and other relevant international standards. These certifications serve as a benchmark for evaluating machinery reliability and performance.

In addition to compliance, certifications can also influence resale value. A machine with recognized import export certifications often holds a higher resale value, as it meets stringent quality and safety criteria that potential buyers look for. A survey conducted by TechNavio highlights that 74% of manufacturers prioritize certified machinery during procurement for this very reason.

Tip: When shopping for CNC lathes, consult with industry experts or attend trade shows to gain insights on certified models that best fit your operational needs, ensuring your investment is both viable and valuable.

Key Certifications to Look for When Buying CNC Lathe Machines

When purchasing a CNC lathe machine, understanding the key certifications can significantly enhance your decision-making process. Certifications serve as a guarantee of quality and compliance with industry standards, making them crucial for both efficiency and safety. Two primary certifications to consider are ISO 9001 and CE certification. ISO 9001 indicates that the manufacturer has a quality management system in place, ensuring that they consistently produce high-quality machines. On the other hand, CE certification is essential for products marketed in Europe, signifying conformity with health, safety, and environmental protection regulations.

Another important certification to keep an eye out for is the UL certification, which is particularly relevant for electrical safety. Ensuring that your CNC lathe machine meets UL standards can help prevent electrical hazards and improve reliability. Additionally, consider certifications specific to the industry or region, such as ASME for pressure vessels or specific energy efficiency ratings. By prioritizing these certifications, you can make informed decisions and invest in a CNC lathe machine that aligns with your operational needs and safety standards.

Understanding Import Export Certifications for Best CNC Lathe Machine Purchases

| Certification | Description | Importance | Validity |

|---|---|---|---|

| ISO 9001 | Quality Management Systems | Ensures consistent quality of products | 3 years |

| CE Marking | Conformity with health and safety standards | Mandatory for products sold in Europe | Indefinite, subject to compliance |

| RoHS | Restriction of Hazardous Substances | Regulates hazardous materials in products | Subject to changes in law |

| UL Certification | Product safety certification | Ensures safety in electrical products | Annually reviewed |

| AS9100 | Quality management for aerospace | Critical for aerospace industry compliance | 3 years |

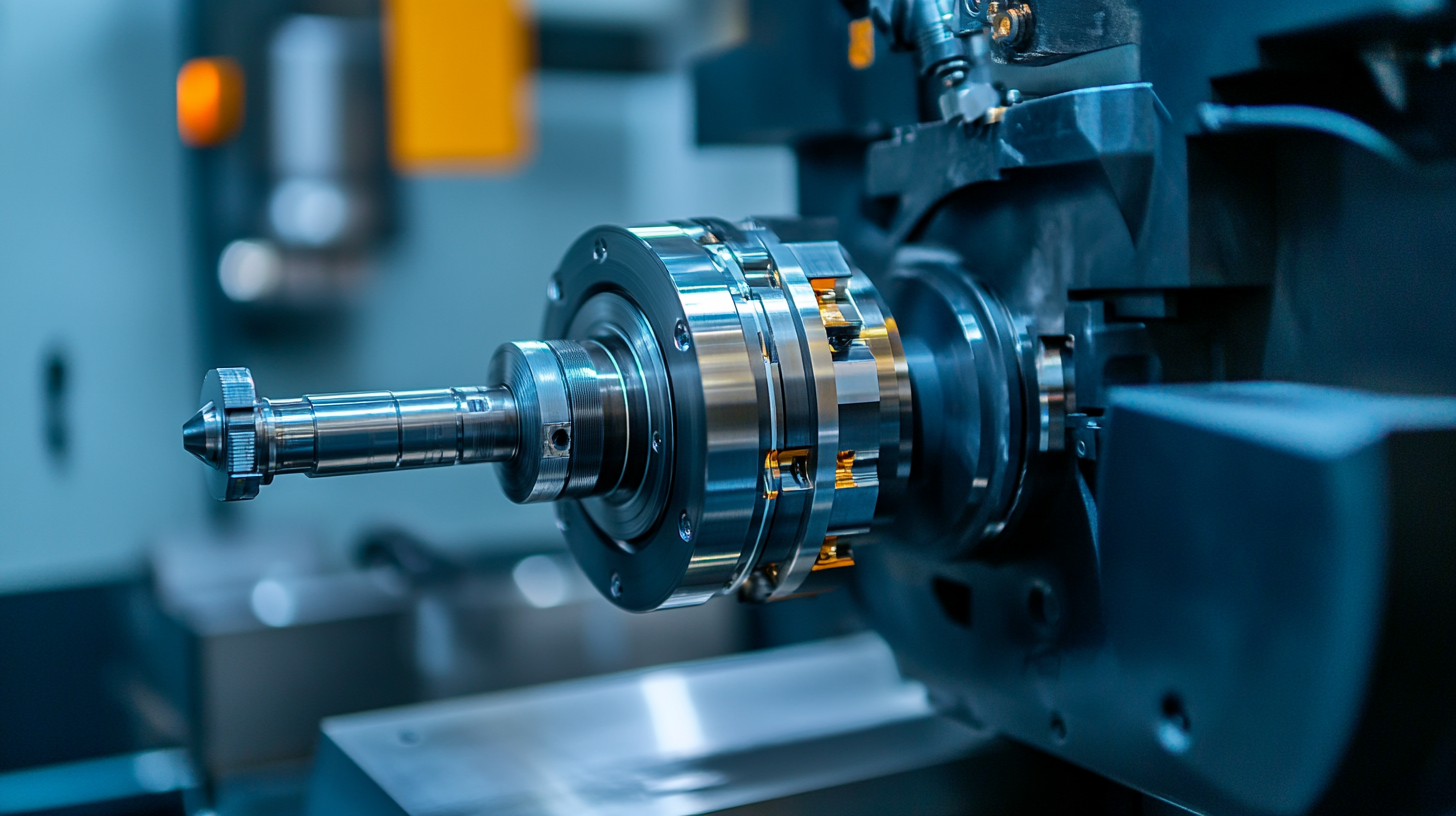

Navigating Regulatory Compliance for CNC Equipment Imports & Exports

When importing CNC lathe machines, navigating regulatory compliance is crucial for a seamless transaction. Different countries impose varying certification requirements, which can impact the efficiency and legality of equipment imports and exports. For instance, in the U.S., the machinery may require compliance with OSHA and ANSI standards, in addition to specific certifications that attest to the equipment's safety and performance. Prior to purchasing, it's essential to confirm that your suppliers have the necessary certifications to avoid delays and potential penalties.

When importing CNC lathe machines, navigating regulatory compliance is crucial for a seamless transaction. Different countries impose varying certification requirements, which can impact the efficiency and legality of equipment imports and exports. For instance, in the U.S., the machinery may require compliance with OSHA and ANSI standards, in addition to specific certifications that attest to the equipment's safety and performance. Prior to purchasing, it's essential to confirm that your suppliers have the necessary certifications to avoid delays and potential penalties.

Tips: Always verify the import regulations of your destination country. Utilize resources from trade organizations and government websites to obtain up-to-date information on compliance requirements.

Additionally, factors like the evolving geopolitical landscape affect sourcing decisions. The recent tensions and shifts in supply chains can influence availability and pricing. For instance, while many businesses have long relied on imports from China due to competitive costs, exploring alternatives in other nations, such as Vietnam, may present new opportunities. In fact, Vietnam's exports are expected to grow in 2024, which could lead to a broader supplier network for CNC equipment.

Tips: Regularly assess your supply chain for diversification opportunities to mitigate risks associated with geopolitical factors. Keeping abreast of emerging market trends is vital in making informed purchasing decisions.

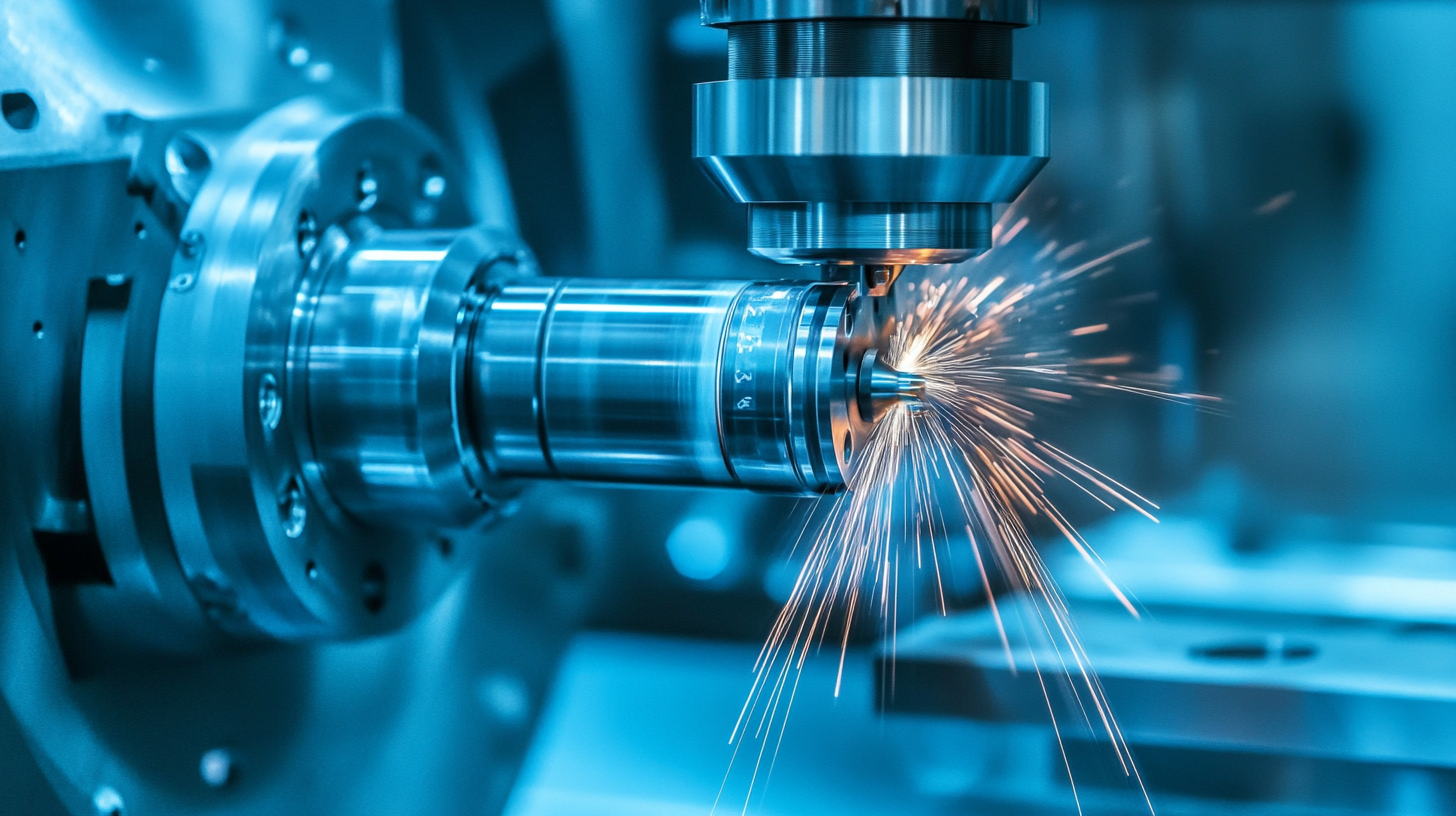

How Certifications Impact the Quality and Reliability of CNC Machines

In the competitive landscape of CNC lathe machine purchasing, understanding import-export certifications is crucial for ensuring quality and reliability. Certifications such as IATF 16949 play a significant role in the manufacturing process, signifying that a company adheres to stringent quality management systems specifically tailored for the automotive sector. When you choose a CNC lathe machine from a certified manufacturer, you are more likely to invest in equipment that meets recognized standards, enhancing both performance and longevity.

Moreover, certifications can directly impact the buyer’s confidence. A manufacturer that has obtained relevant certifications tends to have a more regulated approach to production and quality control. This not only reflects the credibility of the machine but also ensures that the components used are of high quality. For instance, as seen in the recent achievement of IATF 16949 certification by a leading company, this recognition underscores their dedication to quality improvements and customer satisfaction, making their CNC machines a worthy investment for businesses seeking reliable operations. As you navigate the complexities of purchasing CNC lathe machines, prioritizing those with recognized certifications is essential for securing the best machinery for your needs.

Understanding the Cost Implications of Certification in CNC Purchases

When purchasing a CNC lathe machine, understanding the cost implications of import-export certifications is crucial. According to a report by the International Trade Administration, nearly 70% of companies report that adherence to certification standards significantly affects their overall project budgets. This is particularly pertinent when importing CNC machines, as various certifications—such as ISO 9001 for quality management systems—can lead to increased costs. Businesses must not only account for the certification fees but also for potential delays due to compliance testing and inspections, which can extend lead times and affect cash flow.

Furthermore, understanding the impact of certification on pricing can illuminate investment decisions. A study published in the Journal of Manufacturing Processes indicates that CNC machines with recognized certifications can command up to a 20% premium in the resale market. This potential long-term value should be weighed against initial certification costs, especially for companies aiming for sustainability and quality assurance in their manufacturing processes. The transparency that comes with recognized certification can enhance customer trust and business reputation, thereby leading to increased sales opportunities in a competitive market.

Understanding Import Export Certifications Cost Implications for CNC Lathe Machines

This chart illustrates the average certification costs for CNC lathe machine purchases across various certification types. Understanding these costs can help buyers make informed decisions when importing or exporting CNC machinery.